Manufacturing operations with Microsoft Dynamics 365 unified platform.

Intelligent, insight-driven, and sustainable – a new era for manufacturing in a rapidly evolving market landscape.

The new era of manufacturing is here. Whether your organisation is focused on discrete or process manufacturing, manufacturers must rapidly adapt in response to changing market demands and technological innovation – while balancing efficient and sustainable operations.

Streamlined Production Processes

Effective Supply Chain Management

Quality Control and Compliance

Warehousing

Resource Optimisation

Data-Driven Decision Making

Customer-Centric Approach

Agile Adaptation to Market Changes

Capabilities and Benefits

Adaptive Innovation

Data-Driven Insights

Enhanced Customer Engagement

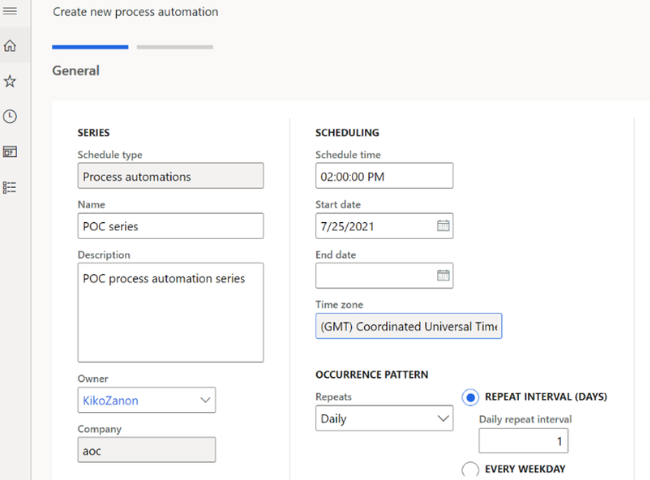

Process Automation

Scalability and Flexibility

Unified Platform

Microsoft Dynamics 365 addresses various challenges in the Manufacturing industry

Complex Supply Chains

Production Inefficiencies

Quality Control and Compliance

Lack of Data-Driven Insights

Customer Demands and Customisation

Maintenance and Downtime

Communication and Collaboration

Legacy Systems and Integration Challenges

Regulatory Changes and Compliance

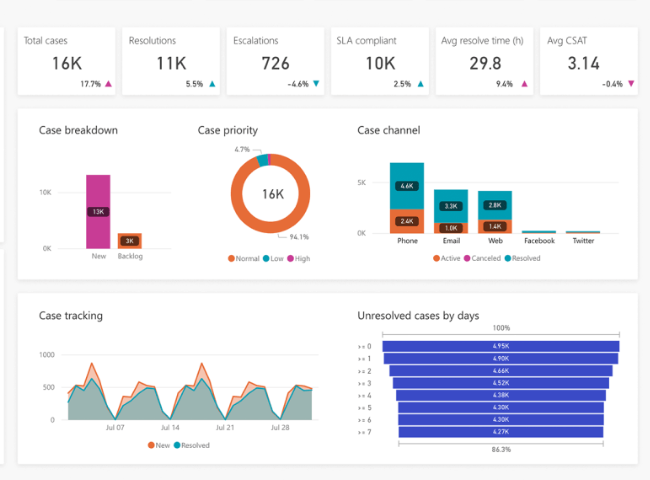

CAPTION PLACEHOLDER

Related Insights & Articles

Lazkam’s Strategic Move: Adopting LS Central to Optimise Operations

Why LS Central Built on the globally-trusted Microsoft Dynamics 365 Business Central platform, LS Central…

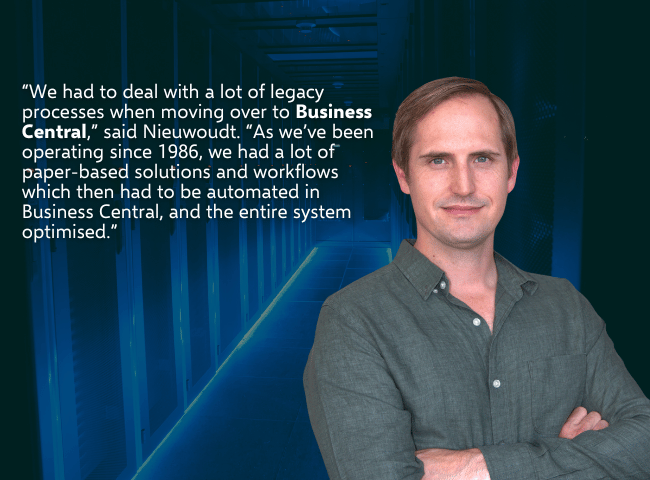

ControlGear Instramac: From Great Plains to Next-Gen Dynamics 365 Business Central

To migrate from Great Plains to Dynamics 365 Business Central while smoothly integrating customisations and…

Deeply rooted in partnerships, expertise and the best solutions

By now, businesses in all sectors understand that digital transformation is a necessity and no…

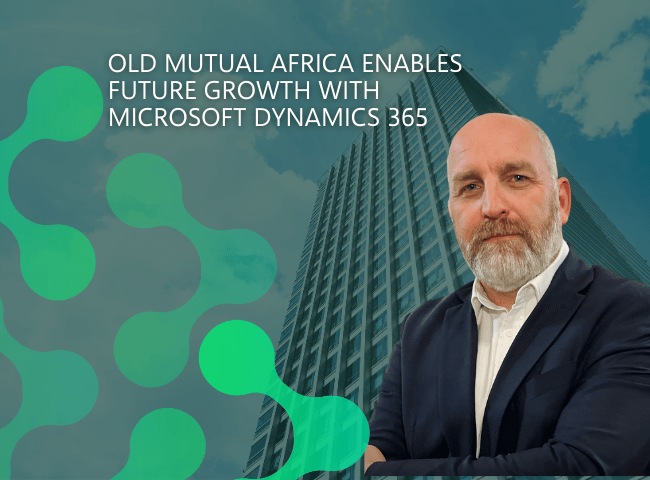

Old Mutual Africa’s Finance Transformation with Microsoft Dynamics 365

Transforming Finance and Operations at Scale: Old Mutual Africa’s Success Story with Braintree and Microsoft…

Streamlining Business Operations and Growth For Frontier Co with LS Central

The Challenge FrontierCo found itself researching new methods of attaining their business goals and potential.…

Braintree Partners With Rolux To Take Lawn Care and Customer Service To The Cloud

The Challenge Tracy Williams “We found that customers were buying products and spares out of…

Braintree: Certified LS Retail Diamond Partner 2024

Braintree Qualifies as LS Retail Diamond Partner for 2024 Leading IT solutions provider and trusted…

Eduvos simplifies student enrolment experience from 90 days to instant with Microsoft and Dynamics 365

Download The Success Story Eduvos identified a critical obstacle impeding their operational efficiency: the lack…